INTERESTS

Micro 3D LDED (Laser-directed Energy Deposition)

Micro laser-based 3D printing of metallic design describes as a technique that enables the facile fabrication of 3D metal structures through the thermal fusion of metal powders using highly focused laser energy. The resulting structures are small and versatile, with potential applications in micro-metal structure repair, printed electronics, MEMS, electronic circuits, 3D interconnectors, and micro energy storage devices.

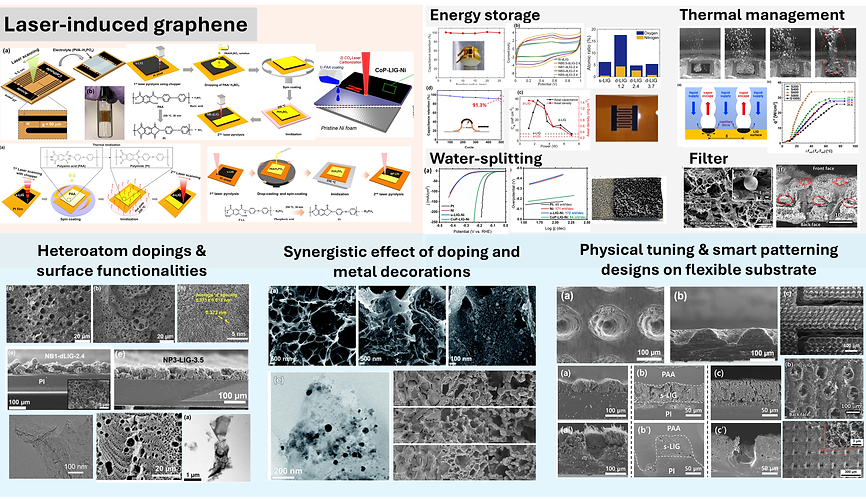

Laser induced graphene and its applications

Laser-induced Graphene (LIG), an alternative form of graphene, is the product of a revolutionary technique, employing CO2 laser scriber for the direct conversion of polymers into porous graphene under ambient conditions. LIG possesses graphene’s exceptional properties, with the advantage of being easy, fast, and cheap to produce. LIG can also be acutely scribe highly customizable patterns with ease and further processed with various techniques and chemical additives to improve its properties. LIG has been explored to utilize in moisture and gas sensors, strain sensors, compact wearable devices, supercapacitors, and environmental applications.

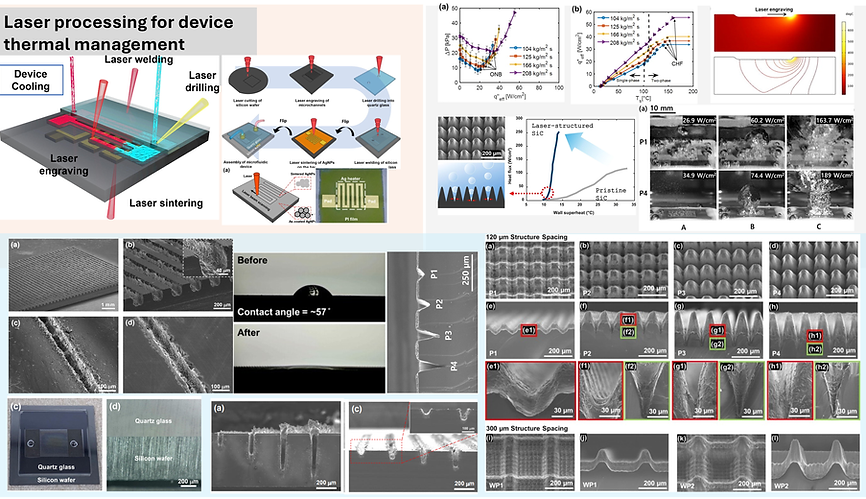

Laser processing for device thermal management

Laser texturing using a galvanometer scanner enables rapid material processing within minutes, with programmable surface patterns and precisely focused energy for micro-level machining. The resulting laser-induced micro/nanostructures enhance wettability and significantly improve pool boiling performance by providing favorable conditions for bubble formation